Global industries are increasingly reliant on plastic resin—a foundational material in products ranging from food packaging to automotive components.

The global packaging resins market alone was valued at USD 233.78 billion in 2023 and is projected to soar to USD 429.67 billion by 2032, growing at a 7.1% CAGR. This explosive demand is reshaping global supply chains and pushing countries to strengthen their roles in production and logistics.

Canada is emerging as a critical player in this evolving landscape. With its abundant natural resources, advanced infrastructure, and commitment to sustainable practices, Canada is well-positioned to support the growing global demand for plastic resin.

However, rising environmental regulations, supply chain disruptions, and shifting trade policies present challenges for resin producers and distributors. Meeting global demand now requires not just increased production but also smarter, more sustainable logistics solutions.

In this blog, we’ll explore how Canada is shaping the future of global plastic resin supply chains—diving into market trends, sustainability efforts, technological advancements, trade policies, and the critical role of logistics partners like WTC Group.

Global Market Trends and Canada’s Position

The plastic resin market is undergoing significant shifts as industries adapt to evolving consumer demands and supply chain pressures. One of the biggest drivers of growth is the rising demand for sustainable and durable packaging materials across sectors like food and beverage, healthcare, and consumer goods. This surge is pushing producers to scale operations and modernize supply chains to meet global needs.

Asia Pacific currently dominates the market with a 49.98% share in 2023, largely due to manufacturing hubs in China and India. However, North America is quickly gaining ground, with the U.S. packaging resins market expected to grow to USD 51.62 billion by 2032.

Canada is well-positioned to capitalize on this growth. Alberta, in particular, is becoming a hub for plastic resin production, attracting investments due to its abundant propane and natural gas reserves. These resources give Canadian producers a competitive edge in meeting global demand for plastic resin.

At the same time, global supply chain disruptions—triggered by the COVID-19 pandemic and geopolitical tensions—have exposed vulnerabilities in resin distribution. Countries are rethinking logistics strategies to ensure reliable delivery of raw materials. Canada’s strategic location and robust infrastructure, including modern ports and rail networks, give it a huge advantage in this evolving market.

Additionally, the global push for environmental accountability is driving innovation in resin production.

Sustainability and the Circular Economy

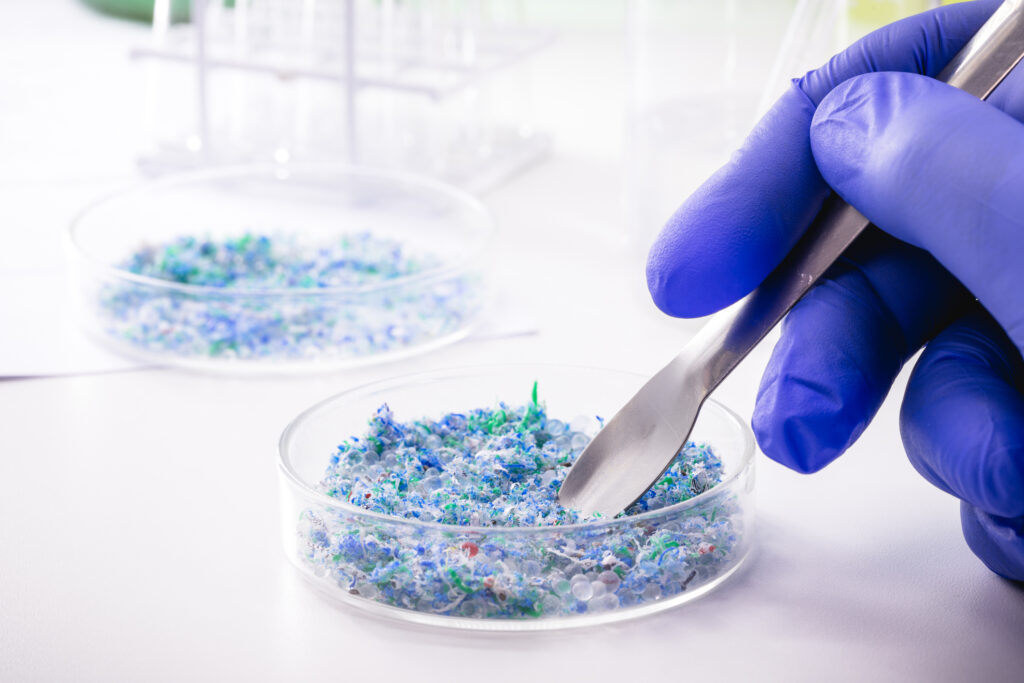

As global demand for plastic resin continues to grow, so does the pressure to address its environmental impact. Industries worldwide are prioritizing sustainability, and Canada is no exception. Canadian resin producers are embracing circular economy principles—focused on minimizing waste and maximizing resource efficiency—to meet environmental standards and market expectations.

A key part of this shift involves reducing plastic waste at every stage of production and distribution. Programs like Operation Clean Sweep (OCS), led in Canada by the Chemistry Industry Association of Canada (CIAC) Plastics Division, are driving efforts to achieve zero plastic resin loss.

Companies like WTC Group are leading by example in adopting sustainable logistics solutions. As a proud member of Operation Clean Sweep, WTC Group has invested in advanced, fully automated resin-handling systems designed to minimize material loss and environmental impact. This commitment to sustainability not only safeguards the environment but also streamlines operations for efficiency and reliability.

Innovation in sustainable materials is also gaining momentum. Canadian companies are investing in bio-based and recyclable plastic resin alternatives, such as PLA (polylactic acid) and PHA (polyhydroxyalkanoates). These bioplastics are designed to reduce dependency on fossil fuels and offer better end-of-life solutions through compostability and biodegradability. The global shift toward sustainable packaging materials further incentivizes Canadian producers to explore these environmentally responsible options.

Technological Advancements in Resin Production

Canadian resin producers are adopting cutting-edge technologies to boost efficiency and sustainability in response to growing global demand for plastic resin. Fully automated systems—featuring pneumatic vacuum lines, automated bagging, and robotic palletization—are streamlining production while reducing material loss and environmental impact.

WTC Group is at the forefront of this shift, embracing all these technologies and more. Their state-of-the-art facilities utilize advanced AI-driven tracking systems and RFID technology for real-time monitoring of resin handling and logistics. This automation improves operational efficiency, reduces human error, and ensures safer, cleaner resin transport.

Additionally, WTC Group’s investment in energy-efficient production methods and automated quality control systems allows for greater output while minimizing environmental impact. These innovations not only align with global sustainability goals but also position WTC Group and Canada as leaders in responsible and scalable plastic resin production.

Impact of Trade Policies and Agreements

Trade policies and international agreements significantly shape the plastic resin industry, influencing production costs, export opportunities, and market competitiveness.

Canada benefits from several strategic trade agreements that support plastic resin exports. The United States-Mexico-Canada Agreement (USMCA) simplifies trade between Canada, the U.S., and Mexico, reducing tariffs and streamlining cross-border logistics. This agreement is particularly advantageous for Canadian resin producers targeting North American markets, offering faster, more cost-effective shipping routes.

Globally, the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) opens doors to rapidly growing markets in the Asia-Pacific region. With Asia Pacific dominating the plastic resin market, this agreement positions Canada to capitalize on increasing demand for plastic resin in countries like Japan, Vietnam, and Australia.

However, global trade tensions and protectionist policies pose challenges. Tariffs on petrochemical products and shifts in international trade relations can disrupt supply chains and inflate production costs. Additionally, growing environmental regulations in international markets are reshaping trade dynamics. Countries are imposing stricter standards on plastic products, pushing exporters to adopt more sustainable practices.

Canada is well-positioned to expand its plastic resin exports and strengthen its global market presence because it is taking steps to navigate these complex trade landscapes and prioritizing sustainable practices.

The Role of Canadian Infrastructure in Supporting Exports

Canada’s robust infrastructure is a key factor in its growing influence within the global plastic resin supply chain. Efficient transportation networks, modern ports, and advanced logistics hubs enable seamless movement of plastic resin from production sites to international markets.

Strategically located facilities, like WTC Group’s Kingsway Terminal, play a pivotal role in this process. The terminal’s 170,000 sq. ft. cross-docking facility and fully automated resin packaging lines significantly boost Canada’s resin handling capacity. With the ability to process up to 480,000 metric tonnes annually, WTC Group’s infrastructure ensures faster and safer product movement through the Port of Vancouver—one of Canada’s busiest export hubs.

Canada’s expansive rail and highway networks further strengthen its position. Access to major North American trade routes allows producers to efficiently transport plastic resin across borders, reducing transit times and costs. Additionally, proximity to the Pacific Gateway enables direct access to fast-growing Asia-Pacific markets.

WTC Group: Powering Canada’s Plastic Resin Supply Chain

WTC Group is at the forefront of Canada’s plastic resin industry, combining advanced infrastructure and sustainable logistics to meet global demand. Their Kingsway Terminal features fully automated resin packaging lines equipped with pneumatic vacuum lines, automated bagging, and robotic palletization—ensuring efficient, secure, and environmentally responsible operations.

By prioritizing innovation and sustainability, WTC Group simplifies complex supply chains and supports Canada’s expanding role in the global market. Their seamless logistics solutions give resin producers a competitive edge in reaching key markets worldwide.

Ready to optimize your plastic resin supply chain?

Contact WTC Group today to discover how our logistics solutions can help your business grow.